Another significant development is the use of lightweight materials in brake caliper construction. For example, carbon fiber-reinforced calipers offer a combination of high strength and low weight, reducing the unsprung weight of the braking system. This not only enhances performance but also improves fuel efficiency and handling.

Additionally, some brake calipers now incorporate advanced braking systems, such as regenerative braking. Regenerative braking systems harness kinetic energy during deceleration and convert it into electrical energy, which can be stored and reused. This technology not only improves overall efficiency but also reduces wear on traditional braking components.

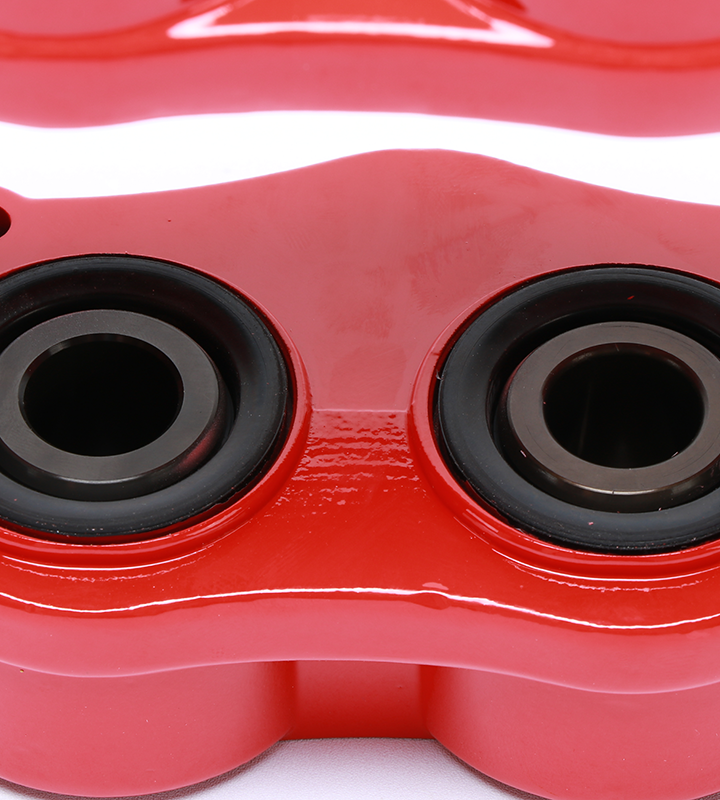

It is all about brake calipers in the world of high-performance automotive components. In this line, ICOOH manufactures a range of brake calipers that are customizable to meet its B2B clients’ specific requests. Our brake calipers are considered top choices among car enthusiasts and professionals around the world because they are built with high performance, durability and safety in mind.

So as to ensure that these calipers perform well, ICOOH makes them using high quality materials that have been precisely engineered. We utilize cutting-edge manufacturing methods in developing lightweight calipers that offer superb braking response and fade resistance. This means our clients can easily incorporate our calipers into different vehicle platforms as they fit multiple applications.

Being your trusted B2B partner, ICOOH offers a full range of technical support and expertise. Ensuring your vehicles both work safely and perform efficiently requires good brake pads; hence, it is important for our beloved customers to receive an excellent service from us. No matter whether one needs custom-made brakes pads for their own cars or some other bigger automobile project —ICOOH has necessary experience as well as capacity to provide you with something really special.

ICOOH is the pioneer in regard to improving the braking performance and the aesthetics of luxury vehicles which is depicted by its innovative line of brake calipers. These precision-engineered components are not just proprietary upgrades; they cause storms in the automotive industry. The lightweight but strong carbon fiber material that has been used to manufacture these calipers easily responds thus making them long lasting and safe for driving. ICOOH’s calipers, specifically designed for B2B partners who want their car moulds and automobile accessories to stand out, combine advanced technology with bespoke design leading them to set new benchmarks within motor racing and luxury cars.

Every vehicle and application is different at ICOOH, so we realize this well enough. That’s why our custom brake calipers are made according to individual needs of our customers. We work collaboratively with car makers and suppliers in order to come up with customized designs that optimize braking ability without compromising on overall vehicle aesthetics. In this way, each one of our light-weight, non-corroding calipers withstands abnormal temperatures and pressures, including those faced by both racing cars as well as daily-driven automobiles thanks to such an innovative carbon fiber manufacturing system.

ICOCH, a leading manufacturer of premium carbon fiber brake calipers, can revolutionize your vehicle’s braking system performance and aesthetics. Our innovative caliper kits offer not only superior stopping power but also an unparalleled touch of luxury and lightweight design to automotive aftermarket accessories. Thus, it is clear that our calipers have been designed with the latest technology in mind.

Malta-based ICOOH has built its reputation on attention to minute particulars when manufacturing high-end brake callipers. All carbon fibre callipers we produce integrate precision engineering and advanced materials for consistent fade-resistant braking even under the most extreme conditions. These calipers are designed as direct replacements for stock components and therefore fit different brands of high-performance models thereby creating new possibilities for customization and individuality.

The role of brake calipers in the automobile industry is essential for vehicle safety and performance. ICOOH, as a renowned producer of top-notch brake calipers, remains committed to manufacturing new dependable products that can fulfill various customers’ needs. The wide range of car producers across the globe considers us a reliable partner due to our expertise in the production of carbon fiber materials and auto parts.

In order to produce our brake calipers, ICOOH knows well how important it is to use only the best materials possible. We employ high-tech manufacturing procedures which ensure accuracy and resilience of our products. Our inclusion of carbon fibers in the creation of brake calipers provides lightweight but strong solutions that improve vehicles’ performances and at the same time reducing them weight-wise. This not only enhances fuel consumption rates but also provides drivers and other persons on board an enjoyable driving experience.

GUANGZHOU WANTIAN INDUSTRIAL CO., LTD established in 2008 and headquartered in Guangzhou, China, is a pioneering force in the realm of automotive modifications, particularly specializing in carbon fiber enhancements. With a steadfast commitment to innovation, the company has secured a prominent position in the industry by developing an extensive range of molds tailored for high-end vehicle models.

Our distinguished team comprises industry experts, featuring top-tier automotive stylists and engineers dedicated to seamlessly integrating groundbreaking concepts with exquisite craftsmanship. At the heart of our operations are advanced manufacturing facilities, allowing us to excel in both wet and dry carbon production. This expertise uniquely positions us to customize high-quality carbon fiber body kits for a diverse range of vehicle models.

We choose premium carbon fiber materials as the primary raw material for manufacturing our enclosures. We ensure that the carbon fiber used meets international standards and undergoes rigorous quality control to guarantee the reliability and durability of our products.

Our experienced design team offers personalized customization based on customer requirements. Whether it's the shape, size, or details of the enclosure,our designers prioritize communication and understanding with customers to ensure the final product fully aligns with their expectations.

Each carbon fiber enclosure undergoes a meticulous handcrafting process. Our craftsmen possess rich experience and skills, translating design concepts into practical products seamlessly,ensuring each enclosure exhibits a high level of craftsmanship and a perfect aesthetic appearance.

Our products have received high recognition in both domestic and international markets. We have successfully exported to over 60 countries and regions, especially receiving widespread acclaim in North America, Europe, Japan, and other regions.

A brake caliper is a component of the braking system that houses the brake pads and applies pressure to the brake rotor to slow down or stop the vehicle.

A brake caliper works by utilizing hydraulic pressure from the brake system to squeeze the brake pads against the rotor, creating friction that slows down or stops the vehicle.

There are several types of brake calipers, including floating calipers, fixed calipers, sliding calipers, and opposed-piston calipers. Each type has its own design and performance characteristics.

Brake calipers are designed to be compatible with specific vehicle models and their corresponding braking systems. It is essential to ensure that the brake calipers you choose are suitable for your vehicle's make and model.

Upgrading to high-performance brake calipers can potentially enhance braking performance by providing better heat dissipation, improved modulation, and increased stopping power. However, the impact may vary depending on the overall braking system and vehicle setup.

ONLINE

ONLINE